Markets

Energy

Natural gas

Natural gas processing is the series of steps used to purify and prepare natural gas for distribution and consumption. This process involves removing impurities so the gas can be used as a fuel for heating and power generation, or can be further processed into LNG.

Adsorbents are widely used in natural gas processing to remove impurities such as water, mercury or hydrogen sulfide. For example, water can form hydrates that can clog pipelines or mercury can have significant negative impacts on aluminum-based cold boxes used in the LNG industry.

Overall, adsorbents are an essential part of natural gas processing, and their use ensures that the gas is of high quality and can be safely transported and used.

Refining

Oil refining is the process of converting crude oil into useful products such as gasoline, diesel, and lubricants. During the refining process, impurities such as water, sulfur, or hydrogen chloride must be removed in order to produce high-quality products.

For instance, chlorides, including both hydrogen chloride (HCl) and organic chlorides, have been a long-standing issue in catalytic reforming operations. To prevent problems such as corrosion, poisoning of downstream catalysts, and product specification issues, on shall remove all chloride species from reformer streams.

This can be achieved through the use of an adsorbent guard bed but the performances are highly dependent on the selected material, feedstock nature, proper tracking and accurate measurements of chloride species.

Hydrogen

Hydrogen is a clean and renewable energy source that has the potential to replace fossil fuels in many applications.

There are several ways to generate hydrogen, including steam methane reforming (SMR), water electrolysis, gasification or biological processes, ….

This has generated a tentative color-code classification of hydrogen generation based on the natured of the used feedstocks and the sustainability and environmental impact of the process.

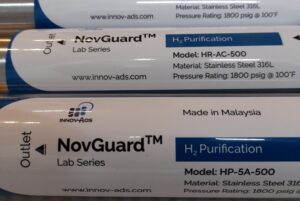

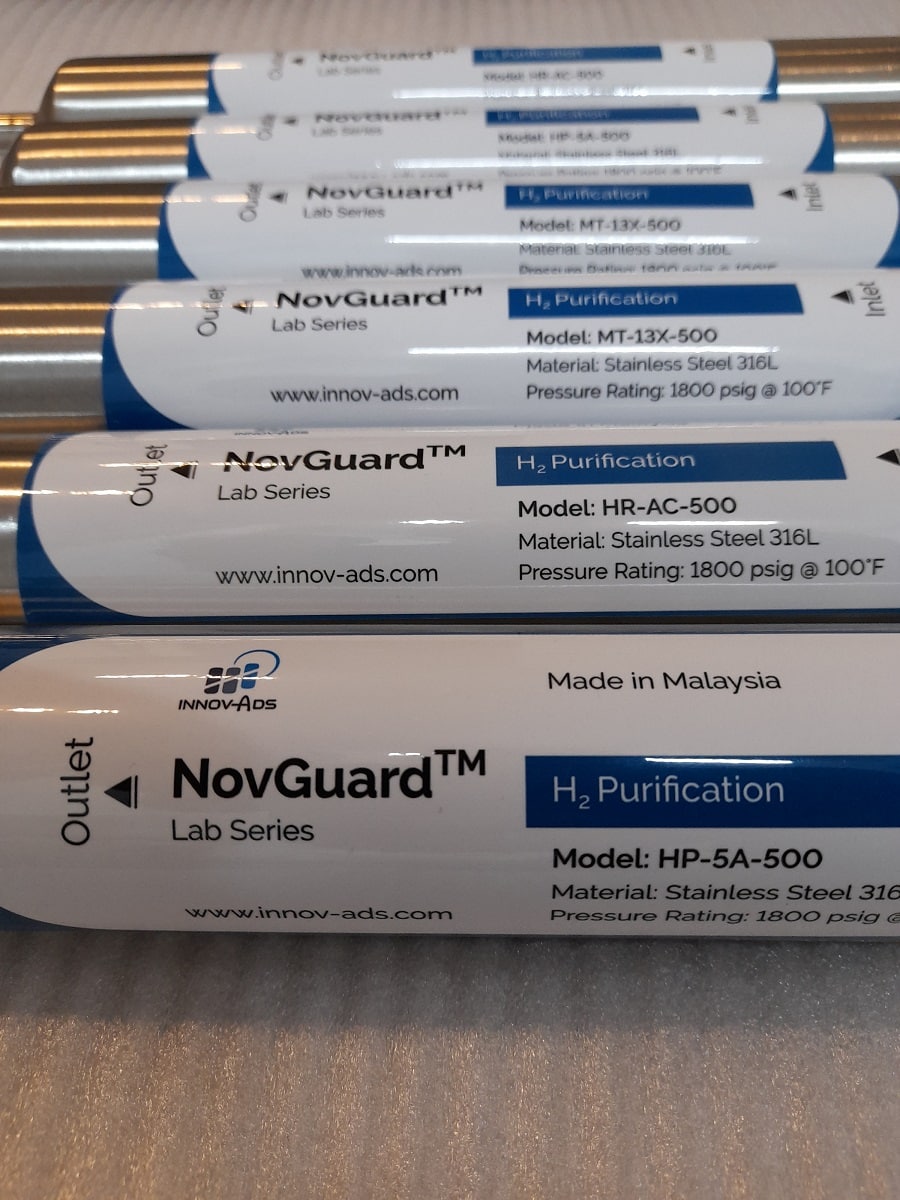

Adsorbents play an important role in providing a clean generation route. For instance, sulfur guard bed are used to remove H2S generated during the SMR process, and Pressure Swing Adsorption technology is widely used to produce high-purity hydrogen.

Biogas

Biogas is a renewable energy source that is produced through the anaerobic digestion of organic matter, such as agricultural waste, food waste, or sewage. It is a mixture of methane, carbon dioxide, and other gases, and can be used as a fuel for heating and power generation.

The anaerobic digestion process involves the use of microorganisms to break down the organic matter in the absence of oxygen, producing biogas as a byproduct.

The biogas may undergo purification to remove any contaminants or to increase the concentration of methane. For instance the water content should be drastically reduced to reduce corrosion in pipelines and storage vessels, and pollutants like siloxanes, ammonia, and H2S should be ideally removed before burning biogas and adsorbents can be used for these different purifications.

We are an independent company providing services and products for adsorption processes

Useful links

Contact

- +60-3-6243-3013

- F-2-10, Pusat Komersial Jalan Kuching, No.115 Jalan Kepayang Off Jalan Kuching, 51200 Kuala Lumpur, Malaysia

- info@innov-ads.com

- linkedIn.com/company/innov-ads